Top 10 Tips To Evaluate The Legal Compliance For PAT in West Bromwich

The UK's regulatory framework for Portable Appliance Testing, or PAT, is fundamentally different than the prescriptive requirements applicable to fixed electrical equipment and fire safety devices. PAT testing, unlike fire extinguisher service, is governed by an broader health-and-safety framework that places more emphasis on risk assessment and duty to care than on mandatory testing schedules. The core legal requirement stems from the Electricity at Work Regulations 1989, which state that electrical systems (including portable equipment) must be maintained to prevent danger. The Regulations are silent on how this should be done, nor do the regulations specify a testing schedule or methodology. As a result, the employer is required to perform an adequate and appropriate risk assessment before determining a maintenance and testing regime. Compliance can't be proven by just a bunch of test certificate. Instead, it must include a demonstrated process of decision-making based on risk, competent execution, and thorough documentation.

1. Electricity at Work Regulations, 1989: The Legal Basis

Regulation 4(2) is the cornerstone of compliance for PAT testing. This states: As may be required to prevent harm, all systems are to be maintained so that they can be prevented, as far it is reasonable practicable. It is an absolute obligation on the part of employers and duty holders to maintain their electrical equipment. The term "systems", which includes portable devices, is used. The regulations don't mention "PAT tests" in particular; instead, they require "maintenance," a concept that encompasses visual inspection, user check, and combined inspection and test. The type and frequency of maintenance is determined by the risk analysis, not by a legal deadline.

2. The Health and Safety at Work Act, 1974 Act 1974

The Health and Safety at Work etc. Act 1974 is the overarching legislation that establishes the general duties employers have towards employees and others. In section 2 of the Act, employers are required to provide, as far as it is reasonable, for the health, safety, and welfare of their employees. Including electrical equipment in safe work systems and plants is part of this. Section 3 extends their duty to other people, like visitors, contractors, or members of the general public. The PAT testing process is a key method of fulfilling these general duties by providing a structured approach to ensuring electrical equipment is safe.

3. Code of Practice of IET for the In-Service Testing and Inspection of Electrical Equipment

While not law itself, the Institution of Engineering and Technology (IET) Code of Practice is the universally accepted benchmark for best practice in PAT testing. The code provides detailed guidelines on implementing an appropriate maintenance regime.

Definitions of appliance classes and types.

Procedures for inspection and testing combined with formal visual inspections.

Based on equipment type and environment, the recommended initial inspection and testing frequencies.

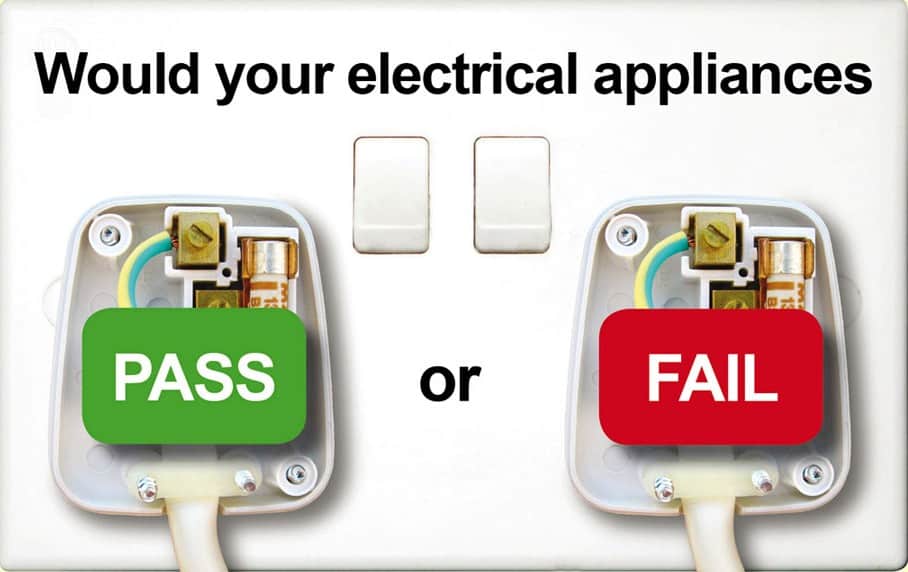

Pass/fail criteria for test results.

Courts and Health and Safety Executives inspectors will use the code to determine whether or not a dutyholder’s regime of maintenance is "suitable and sufficiently." The failure to adhere to the overall regulations can be interpreted by courts and inspectors of the Health and Safety Executive (HSE) as deviations from the code.

4. The Primacy of Risk Assessment

HSE promotes a risk-based PAT approach, moving away the outdated concept that all equipment should be tested annually. The dutyholder must conduct a risk assessment to determine the need, nature, and frequency of inspection and testing. The following are key factors that influence this assessment:

Equipment type. A Class I appliance, in a workshop or low-risk environment, may require regular formal testing.

Construction sites, workshops, and warehouses present a high level of risk. Offices and hotels have a lower risk.

Are users of equipment trained staff, or are they members of the general public.

How old is the appliance and how often has it been damaged?

This risk assessment is what defines a compliant system, not the number of tests performed.

5. The Concept of Competence for Testers

Regulation 16 of the Electricity at Work Regulations (1989) states that anyone working with electrical equipment must have the required technical knowledge to avoid harm. In PAT tests, "competence", does not always require formal qualification. However, the tester must possess:

You should have a good understanding of electricity.

The ability to work with the system in question and have an understanding of it.

Understanding the hazards involved and the precautions needed.

Ability to correctly use and interpret test equipment.

While City & Guilds 2377 is a popular qualification that provides excellent training, competence can be achieved through other means. The duty holder must be able show that the person who conducts the testing is competent.

6. Documentation Requirements and Record-Keeping

The Electricity at Work Regulations are not explicit in their requirement for record keeping. Regulation 29 however states that proving due diligence and taking all reasonable steps in order to avoid committing the offense is a defence. Due diligence is best demonstrated by comprehensive records. A compliant record-keeping system should include:

An asset register of equipment.

The risk assessment and maintenance plan should be documented.

Reports for each inspection and test including the appliance description, results of tests, pass/fail status and date of next testing.

HSE or the local authorities can easily access these records.

7. Appliance Labelling and Identification

Labelling is an important part of a PAT system that's compliant. Each appliance that has undergone a formal combined inspection and test should be labelled with:

A unique asset ID number that ties it to the record.

The test date.

Date of the next test or re-inspection.

The name or identifier of the tester.

The label serves as a clear indicator to users and inspectors about the appliance's level of compliance. Labels need to be durable, not metallic, and not conductive.

8. The HSE Enforcement Position and "Myth-Busting".

The HSE has worked actively to clear up misconceptions regarding PAT testing. They stress that:

No legal requirements exists for equipment to be tested annually.

There is no requirement for businesses to hire a third party contractor if they are able to test themselves.

Visual inspections are often more important than testing electronically and can identify most faults.

An enforcement officer will look for a risk-based approach. A company that tests its equipment without any support in the form of a risk assessment will be seen as less favourably by an enforcement officer than one who can demonstrate a more robust risk assessment and justify a longer interval between testing for equipment with low risks.

9. PUWER: 1998 – Interaction with other Legislation

The Provision and Use of Work Equipment Regulations 1998 (PUWER) also applies to portable appliances. PUWER states that all work equipment must be safe, fit for the intended use and maintained in a safe manner. It also requires regular inspections to make sure it is safe. In Regulation 6, inspections are specifically required when the safety of work equipment depends on its installation. The PUWER inspection and maintenance regulations for electrical work equipment are met by PAT testing, which is a critical method.

10. Insurance implications and due diligence

Insurance companies can have their own requirements, even though the law is based upon risk assessment. As a condition to coverage, an insurance policy could stipulate that PATs are conducted by a third party annually. A claim could be invalidated if this is not adhered to. In the event of a serious electrical accident, insurers and HSE inspectors will first examine the dutyholder’s PAT test records and risk assessments. A documented, risk-based approach is the best possible proof of due diligence. It also provides a strong defence against prosecution and invalidated insurance claims. Read the top West Bromwich compliance services for website recommendations.

Top 10 Tips On Response Time For Fire Extinguisher Maintenance in West Bromwich

In the area of fire safety compliance, response times for servicing aren't simply something to be considered as a convenience, they are an essential element in maintaining continuous legal compliance and operational security. The Regulatory Restructuring (Fire Safety) Order (2005) requires that equipment for fire-fighting maintain a high level of efficiency. Damaged, missing, or discharged equipment constitutes a grave violation of the order. In order to minimize your exposure to risk, maintain insurance coverage, and ensure operational continuity, a provider must be capable of responding to emergency request and planned demands promptly. The slow response time can make your business vulnerable, interrupt processes during audits and reveal inadequate due diligence. To assess the response capabilities of a service provider that include routine calling outs in emergency situations, it is important to understand the different levels of service available, the geographical limitations as well as contractual obligations and operational capacities that allow swift and efficient response.

1. Timelines for scheduled service appointments in West Bromwich

The efficacy of the company's system of scheduling annual routine services is a reliable indicator of their operational proficiency. A well-organized company will usually contact you approximately 4-6 weeks prior to your certificate expiry date to schedule your next annual service. They should offer a variety of scheduling options and must be able to provide an exact AM/PM slot, or a date confirmed for the engineer's arrival. If you have to schedule more than 3 months in advance, this could indicate that your company is not adequately staffed or is not managing its resources properly or is overextending its reach. This can lead to a possible delay in the certification coverage.

2. Definitions and Tiers of Emergency Callout Response

Not all reactive phone calls are the same. Trustworthy service providers provide clear levels of response to emergencies, with each offering a time-based guarantee. The most common urgent request, such as a missing or defective extinguisher (for example), may be able to receive a response target of between 24-48 hours. A high-priority emergency (e.g. several units being disposed of following an incident that is minor or a major defect discovered in an audit) is best handled more quickly, usually within a few hours or even the next day. This must be clearly defined in any contract or service agreement to ensure that expectations are managed.

3. Geographical coverage and local engineer availability in West Bromwich

Geographical West Bromwich is directly related to response time. A multinational company may be a well-known brand but they rely on local engineers. If you wish to ensure that they can respond rapidly in an emergency, or on a regular basis, it is crucial to inquire if the engineers are located in the local area, or if any of them travel a long distance. If a service has a dense network local engineers, they are able to respond quicker and with less cost. Always ask "Where is your closest engineer to our postcode?"

4. Service Level Agreements (SLAs) that ensure response times, in West Bromwich

The primary thing to be considered is whether your Service Level Agreement guarantees response times. The flims promise of "attending promptly" does not mean anything. A robust SLA contains measurable and meaningful Key Performance Indicators like "We accept a service request within two hours" or "We attend the site to deal with urgent emergencies within four hours." These contractual guarantees offer protection to you in case the provider of service fails consistently to meet its obligations.

5. Communication Protocols and Helplines in West Bromwich

The efficiency of communication is essential to speedy response. Determine the protocol of the service provider for receiving and processing requests for service. Does the company have a designated customer support helpline or dedicated email address to handle urgent problems? Do they operate during normal business hours and afterwards? The most reliable providers have an immediate phone line to a coordinator who will send an engineer right away, without being stuck in a long queue. This is vital in the event of an emergency.

6. Support for weekends and out-of-hours in West Bromwich

As with faults are not a part of the standard 9-5 working hours. The ability to contact support in the event of an out-of-hours incident or in high-risk situations (e.g. data centers manufacturing 24/7 or care homes.) is essential. It is important to check whether the provider provides an emergency callout that is available 24/7 service, or if it's limited to work days. If they do provide out-of-hours support, you should inquire about the premium costs and the guaranteed response time for these calls, since this could be quite different from their normal daytime SLA.

7. Fault Resolution vs. Initial Attendance Time

There is a critical distinction between the initial response (where an engineer visits the site and assesses the problem) and the resolution of faults (when the equipment has been repaired or fully replaced and in compliance). A service provider could arrive swiftly to report a malfunctioning extinguisher, but take several days to locate and install a new one, leaving the West Bromwich unprotected. Both of these metrics should be covered within your SLA. A provider should strive to solve common issues such as a missing extinguisher in the first visit.

8. Effect of Response Delays on Compliance and Insurance in West Bromwich

Understanding the implications of slow responses is essential. If you fail to repair an extinguisher damaged or is missing the building may not be conforming to the Fire Safety Order. The Fire Authority can take action against you during an inspection. Furthermore the insurance policy you have will likely be contingent on the compliance of fire safety regulations. A company may make use of a delay of substantial amounts in rectifying a clear error as a reason to deny a claim arguing you have not maintained sufficient security.

9. Manage the Provider Capacity and Workload in West Bromwich

The speed at which you can respond is an indication of the management team's abilities. The ratio of engineers to clients and the way they manage high workloads are crucial concerns to inquire about. A provider who is overstretched may have engineers behind schedule for regular visits or have no ability to respond to emergency situations. Ask the provider how they will handle a situation where you need to replace multiple extinguishers at your site in a matter of minutes. Their response will reveal their capability for large-scale rapid response.

10. Monitoring, reporting and Performance Review in West Bromwich

Professional service providers do not only make promises but also evaluate their performance. They should be able monitor the time to respond for all types of calls. They must also provide you with reports on performance on a regular basis (e.g. every year) to prove that they are adhering to the SLAs stipulated in your contract. This transparency will allow you to conduct a fact-based examination of their service and make them accountable for maintaining high standards for your conformance to the fire safety regulations. Follow the recommended fire extinguisher inspection in West Bromwich for blog recommendations.

Leave a Reply